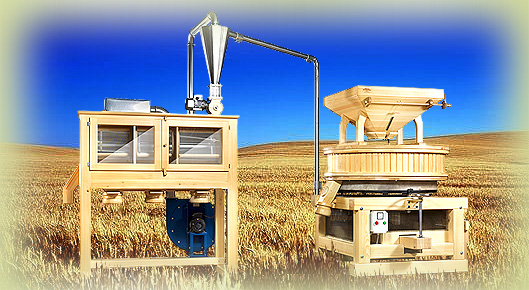

Installation de moulin à farine: A 700 - A 1000 – A 1200 – A 1600

Installation : A 700 - A 1000 – A 1200 – A 1600

Installation avec système pneumatique de transport

Avec le système de transport pneumatique, le moulin reste propre et la farine reste froide.

Performance horaire augmenté de 30% !

Tous nos moulins sont équipés d'un moteur à faible vitesse, ce qui permet de garantir une excellente qualité de la farine !

Revêtement intérieur en acier inoxydable

Important ! Vitre dans la machine de tamisage permettant de contrôler le processus de tamisage !

Performance horaire : env. 170 - 500 kg

Au cours des 20 dernières années, nous avons livré quasi exclusivement des installations équipées avec notre système éprouvé de transport pneumatique. Grâce au flux d'air, le refroidissement n'est pas seulement efficace sur la farine pendant le transport mais également les pierres mêmes, ce qui permet alors d'augmenter le rendement de l'installation de 30 %.

Le système pneumatique garantit aussi une évacuation constante de la farine depuis le moulin vers le système de filtrage, ce qui évite une alimentation en-dessous du niveau requis resp. la surcharge de celui-ci, qui est généralement provoquée par des vibrations au sein même du système de transport qui à leur tour proviennent d'un degré de remplissage différentiel du convoyeur.

Grain mill plant for bakeries

Grain mill with sifter and transport pneumatic.

Grain mill plant

- The grain mill is also available as the smaller model Type A 1200.

- With this grain mill it is possible to produce different sorts of flour and semolina.

- Semolina purifier

- Filter box with air filter bags

- Pneumatic air-conveyor system

- Grain mill Types A 1600 Type A 1200 or Type A 1000

The grounded grain in the mill is transported by a pneumatic air-conveyer to the sieve. In several chambers the flour and semolina is separated in one operation and at the same time the bran is also separated.

In order to increase the share of fine flour, it is possible to take the semolina and grind it again on the finest setting.

To obtain a very white flour the semolina is put into the semolina purifier and is cleaned from the bran particles. Then it is finally ground with the finest setting.

The portion of flour obtained from wheat is approx. 60% to 75% depending on the grinding setting.

In order to produce different types of semolina the sieves can be changed and the mill stones altered. If semolina is needed, then it is necessary to purify it from the bran particles before using it in the semolina purifier machine. The filter box with the air filter bags is for cleaning the conveying air.

Grain mill plant A1200

Grain mill plant with big screen box

Grain mill plant A1200

Grain mill 1600 - base in steel

Mill plant A 700

| Steinmahlwerk | zertifizierte Mahlsteine |

| Gosse, Zarge | aus Kiefernholz |

| Zarge innen | in Nirosta ausgestattet |

| Zahnrad | unerhalb des Trichters |

| Schauglas | im Trichter |

| Regulierung der Mehlfeinheit | mittels Handrad, Magnetfalle |

Untergestell in Metallausführung

Komplett mit Mehlsiebmaschine Type 700

- Ausführung in Kiefernholz mit 3 Kammern

- Mahlkammer innen in Nirosta

- 5 Siebrahmen mit verschiedenen Stärken

und pneumatische Transportanlage

- Zyklon mit Schleuse, Absaugventilator

- Rohrleitung mit Bögen in Nirosta, Filterkasten, Filter

Hulling machine for spelt

Spelling machine with aspiration-system

- Charging hopper and separating device for impurities

- Hulling cylinders

- Adjustment, regulation of cylinders

- Chaff ventilator and the first chaff exhaustion

- Adjusting head of hulling cylinders

- Second chaff exhaustion and dust output

- Separating device for the broken grains

- Outputs of hulled grains of spelt

Cylindrical sieve Type 3 K, 3 KGA, 3 KKA

Cylindrical sieve

- Smaller construction, 3 chambers, 4 outputs (one for bran), fits the grain mills Type A400 - A1600

- Interior fittings in Nirosta

- The sieve box is equipped with viewing windows

- Delivered with one set of spare sieves free of charge

Industrial mill

Industrial mill

- This equipment complies with all security and health requirements and it is authorized to have the sign “CE”.

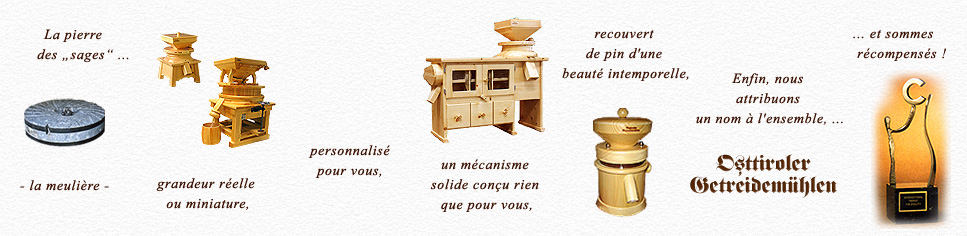

- The Green family is the sole producer of grain mills to be awarded the State Award from the Bavarian State Government.

- We will guide you from the grain to the flour.

- We would be happy to produce an industrial mill tailored to your particular needs.

Osttiroler Getreidemühlen (moulins à grains Osttiroler) | Heidi Green | A-9991 Doelsach, Muehlenstrasse 2

Tel: +43 664 3006160 | E-Mail: og@getreidemuehlen.com | Contact : Contact |